Introduction

Imagine being able to design your own custom robot part — like a camera mount, sensor case, or even full robot chassis — and print it at home like printing a document.

That’s the magic of 3D printing .

In the maker world, 3D printing has become as essential as soldering or coding. It lets DIYers move from breadboards & prototypes → real, durable, professional‑looking hardware.

In this guide, we’ll explore:

- What 3D printing is and how it works.

- The main types of 3D printing for DIYers.

- How robotics enthusiasts use 3D printing.

- Beginner project ideas you can try today.

What is 3D Printing?

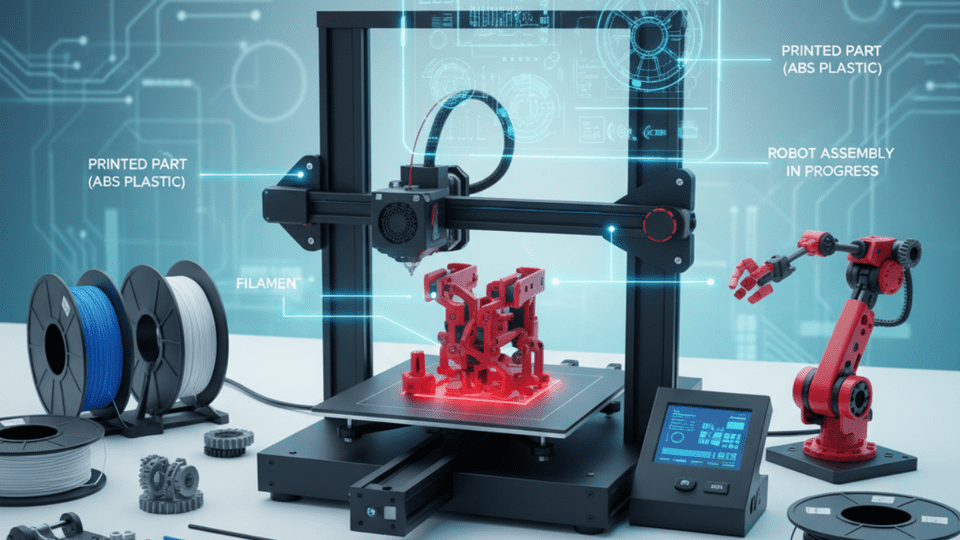

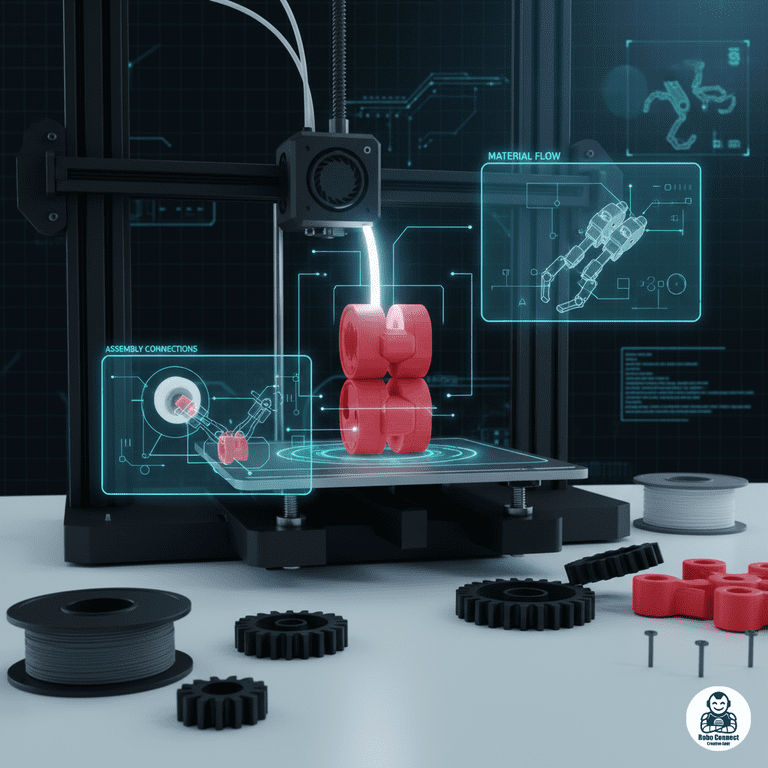

3D printing (additive manufacturing) is the process of creating 3D objects layer by layer from a digital model.

- You design a part in CAD software (Fusion 360, TinkerCAD, SolidWorks, FreeCAD, etc.).

- Software slices it into thin layers.

- The 3D printer builds the part layer by layer with filament or resin.

In short: You “print” objects you designed — not just flat documents.

Popular Types of 3D Printing for Makers

- FDM (Fused Deposition Modeling)

- Melts plastic filament (PLA, ABS, PETG) → builds layer by layer.

- Cheapest, most common for hobbyists.

- Example printers: Creality Ender 3, Prusa i3 MK3, Anycubic Kobra.

- SLA (Stereolithography / Resin Printing)

- Uses UV laser to cure resin.

- High detail, smooth finish, smaller parts → perfect for gears, intricate mechanisms.

- Example printers: Elegoo Mars, Anycubic Photon Mono.

- SLS (Selective Laser Sintering)

- Uses powdered nylon, fused by laser.

- Stronger, industrial grade → rarely used by beginners due to cost.

Why 3D Printing is Great for Robotics

- Custom Parts → Chassis, motor mounts, servo brackets, gear housings.

- Rapid Prototyping → Test designs quickly before CNC/manufacturing.

- Low Cost → Print parts at home instead of ordering special components.

- Creative Freedom → Design unique robots with custom shells, styles.

- Open Source Designs → Thousands of free files online (Thingiverse, PrusaPrinters, Printables).

Steps to Create Your First 3D Printed Robotics Part

- Design: Use simple CAD software (TinkerCAD for beginners, Fusion 360 for advanced).

- Slice: Import into slicer software (Cura, PrusaSlicer) → converts 3D file into layer instructions (G‑code).

- Print: Send to 3D printer with PLA filament → let it build.

- Test Fit: Mount motor, sensor, or PCB inside/custom part.

- Iterate: Re‑design or modify easily (perfect for DIY tinkering).

Pro tip: Start with PLA filament (easy, eco‑friendly, strong enough for robotics). Move to PETG or ABS for higher temp/mechanical strength.

Examples of Robotics Parts Made with 3D Printing

- Wheels & Tires: Lightweight drone/robot wheels.

- Motor Brackets: Custom fit motor holders for robot chassis.

- Sensor Cases: IR sensor mounts, ultrasonic housings.

- Gears & Levers: Replace difficult‑to‑buy plastic gears.

- Robot Arms: Joint + servo modules.

- Full Robot Body: Print a line follower or obstacle‑avoidance bot chassis.

DIY Project Ideas with 3D Printing

- Line Follower Robot Chassis (custom cutouts for sensors).

- FPV Drone Frame (lightweight carbon‑fiber PLA or PETG filament).

- Camera Pan‑Tilt Mount (for Raspberry Pi camera).

- Mechanical Robot Arm (servo‑driven, modular parts).

- Custom Enclosures (Arduino/ESP boards in neat cases).

Tips for Beginners

- Use PLA for easy prints (1.75mm filament).

- Level your print bed properly — 90% of failed prints start here.

- Download free designs first before making your own.

- Keep designs simple (avoid overhangs, use supports for complex geometry).

FAQs

Q1: How much does 3D printing cost?

- Hobbyist printers: 150–150–400.

- PLA filament: $20 (1 kg spool = dozens of parts).

Q2: Can I print strong functional parts?

Yes → use PETG or ABS filaments for strength, or resin printers for precision.

Q3: Do I need CAD knowledge?

Not initially. You can download pre‑made models. Later, simple CAD skills unlock endless custom builds.

Conclusion

3D printing is a game‑changer for robotics makers:

- Lets you build custom robot parts, test ideas quickly, and make your projects look professional.

- Printers are now affordable, filaments are widely available, and tutorials abound online.

If you’re serious about DIY robotics, adding a 3D printer to your maker toolbox is one of the smartest investments you can make.