Introduction

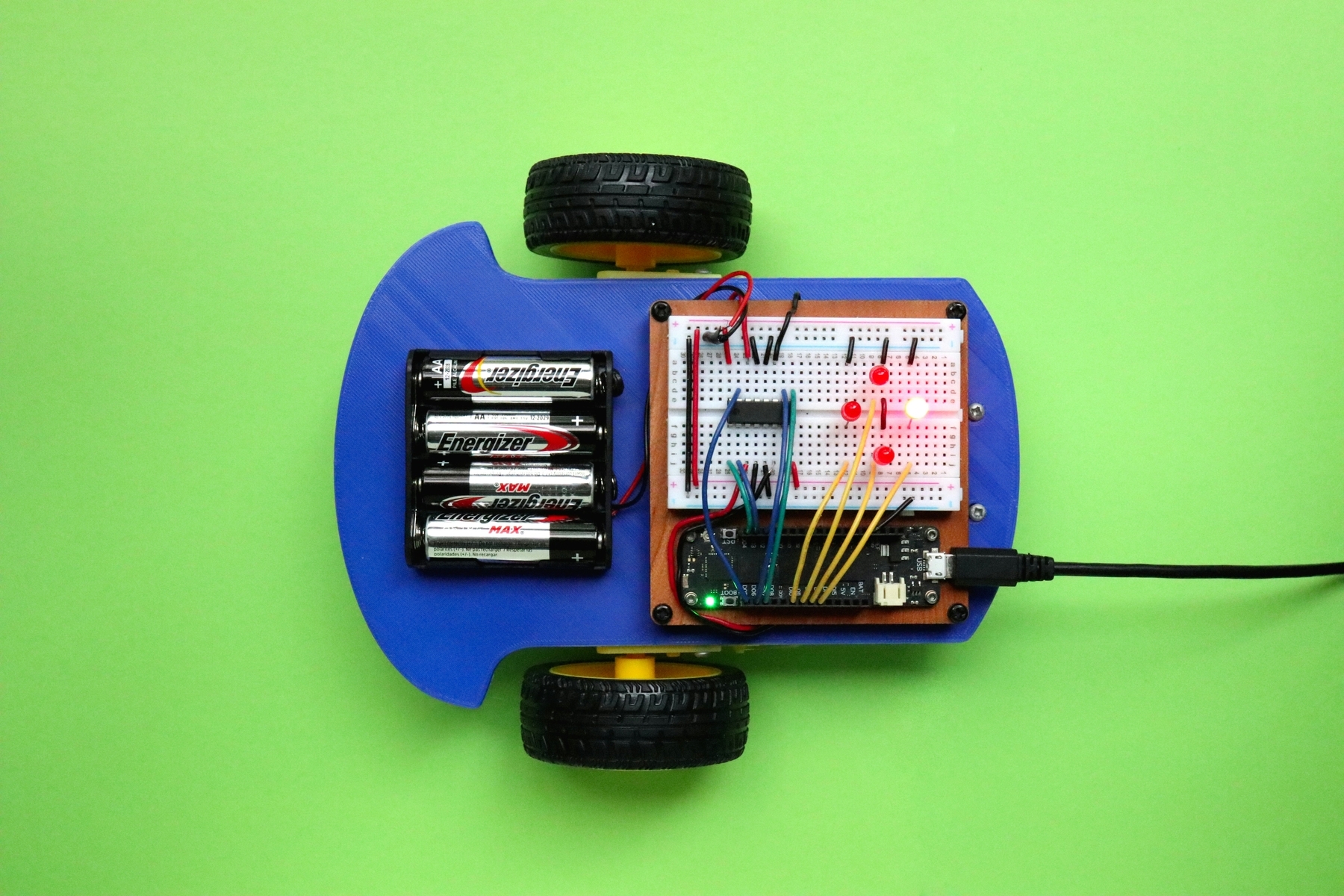

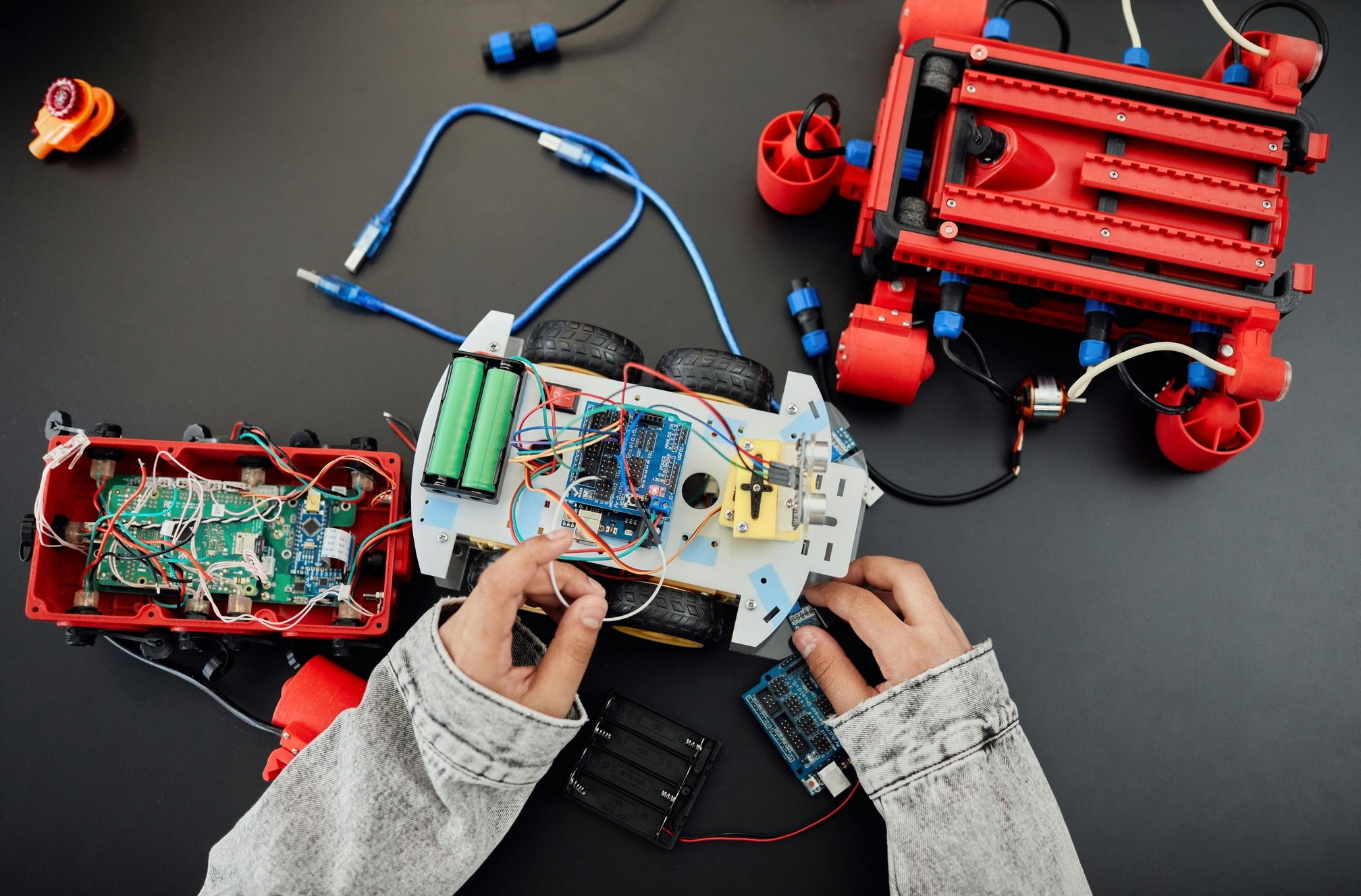

Blinking LEDs and reading sensors is fun… but nothing says “I’m really building robots” like controlling motors with Arduino. 💡

In this guide you’ll learn how to control:

- ⚡ DC motors (for fans, wheels)

- 🎚 Servo motors (for precise angles like robot arms)

- 🔄 Stepper motors (for exact step movements like 3D printers)

We’ll go through wiring basics and ready‑to‑use Arduino code for each.

- Controlling a DC Motor with Arduino

A DC motor spins continuously when powered. Arduino itself can’t handle the high current, so we use a transistor or motor driver (L293D / L298N).

Wiring (transistor method):

- Motor + external 5–9V supply

- NPN transistor as a switch (TIP120 or 2N2222)

- Motor + diode for back‑EMF protection

- Arduino pin 9 → transistor base

Code (DC Motor On/Off):

C++

int motorPin = 9;

void setup() {

pinMode(motorPin, OUTPUT);

}

void loop() {

digitalWrite(motorPin, HIGH); // Motor ON

delay(2000);

digitalWrite(motorPin, LOW); // Motor OFF

delay(2000);

}

⚡ Motor spins 2s, stops 2s, repeats.

Code (DC Motor Speed Control with PWM):

C++

int motorPin = 9; // PWM pin

void setup() {

pinMode(motorPin, OUTPUT);

}

void loop() {

for (int speed = 0; speed <= 255; speed += 5) {

analogWrite(motorPin, speed); // Increase speed

delay(50);

}

for (int speed = 255; speed >= 0; speed -= 5) {

analogWrite(motorPin, speed); // Decrease speed

delay(50);

}

}

💡 Motor gradually speeds up, then slows down.

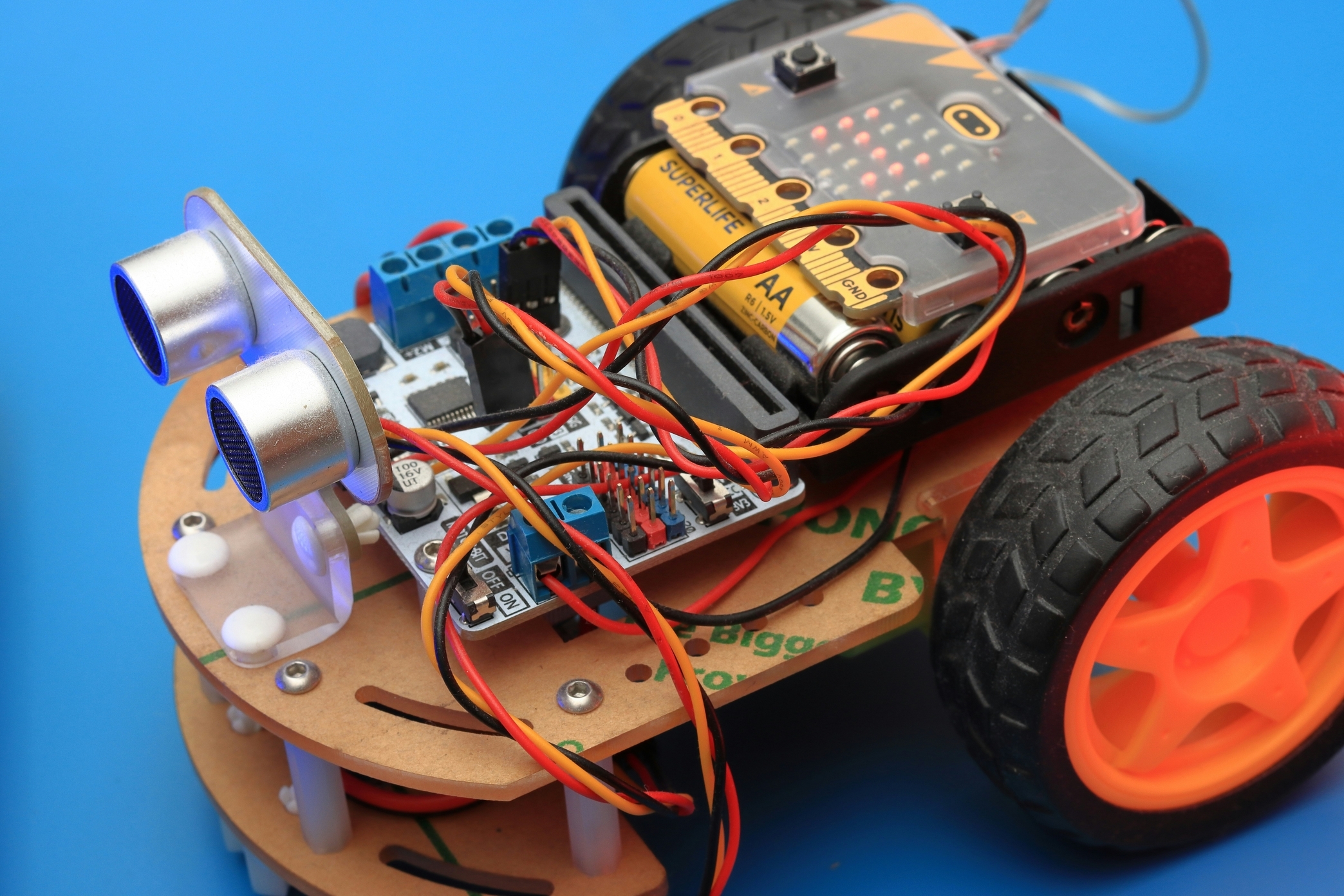

- Controlling a Stepper Motor with Arduino

A stepper motor moves in exact steps (e.g., 200 steps per revolution). Great for 3D printers, CNC machines, precision robots.

We use ULN2003 or A4988 drivers.

Wiring: Stepper → ULN2003 board → Arduino pins 8, 9, 10, 11.

Code (Stepper Sweep):

C++

#include <Stepper.h>

const int stepsPerRevolution = 200; // Motor depends, check datasheet

Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

void setup() {

myStepper.setSpeed(60); // 60 RPM

}

void loop() {

myStepper.step(stepsPerRevolution); // One revolution

delay(1000);

myStepper.step(-stepsPerRevolution); // Backwards

delay(1000);

}

🔄 Motor turns one full revolution clockwise, pauses, then counterclockwise.

FAQs

Q: Can I power a motor directly from Arduino pins?

A: No! Use a transistor or motor driver (like L293D or L298N).

Q: Why is my servo motor vibrating instead of moving?

A: Not enough stable power—use a 5V regulator or external supply.

Q: Can Arduino control multiple motors?

A: Yes! Use multi‑channel motor drivers or multiple PWM pins.

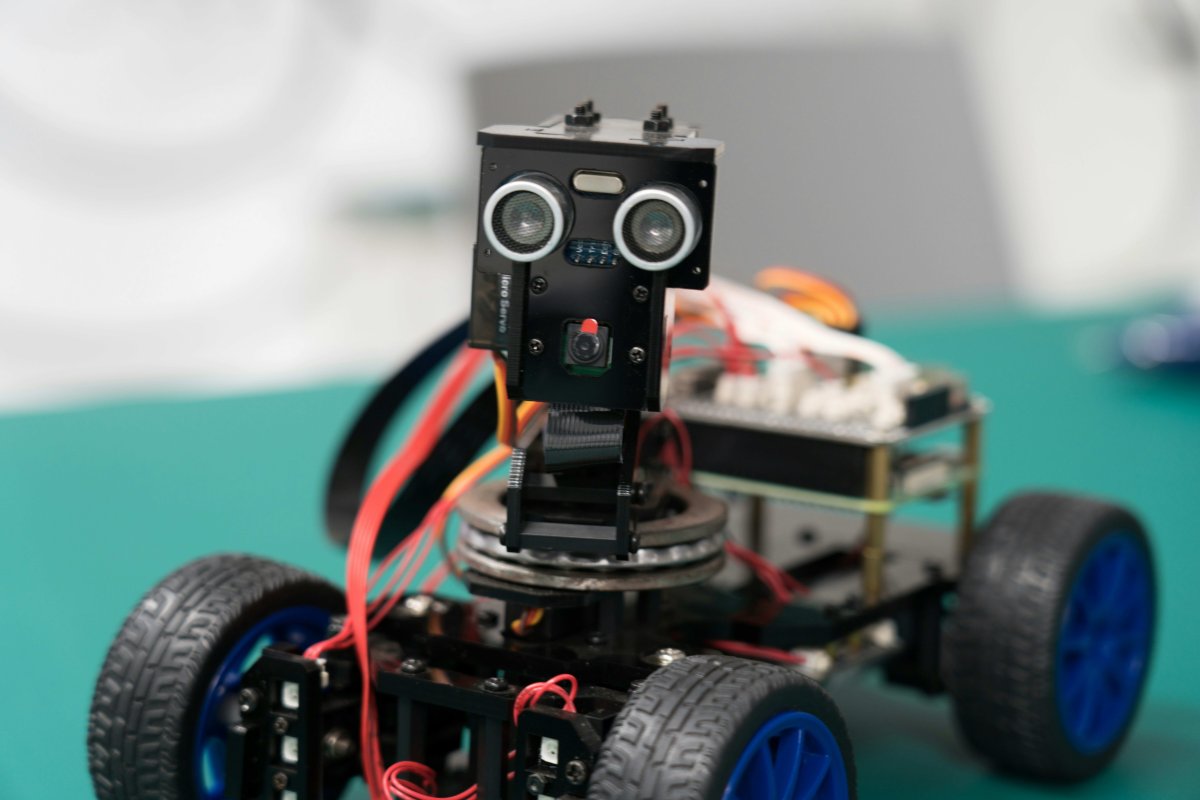

Ideas for Projects with Motors

- Smart fan (DC motor + temperature sensor).

- Robotic arm (servo motors).

- Line follower robot (DC motors + motor driver).

- 3D printer + CNC basics (stepper motors).

Conclusion

With DC, Servo, and Stepper motors, Arduino projects level up from blinking lights to real, moving robots.

- DC = simple spin & speed

- Servo = precise angles

- Stepper = exact steps/revolutions

Once you combine sensors + motors: welcome to the world of actual robotics.