Introduction

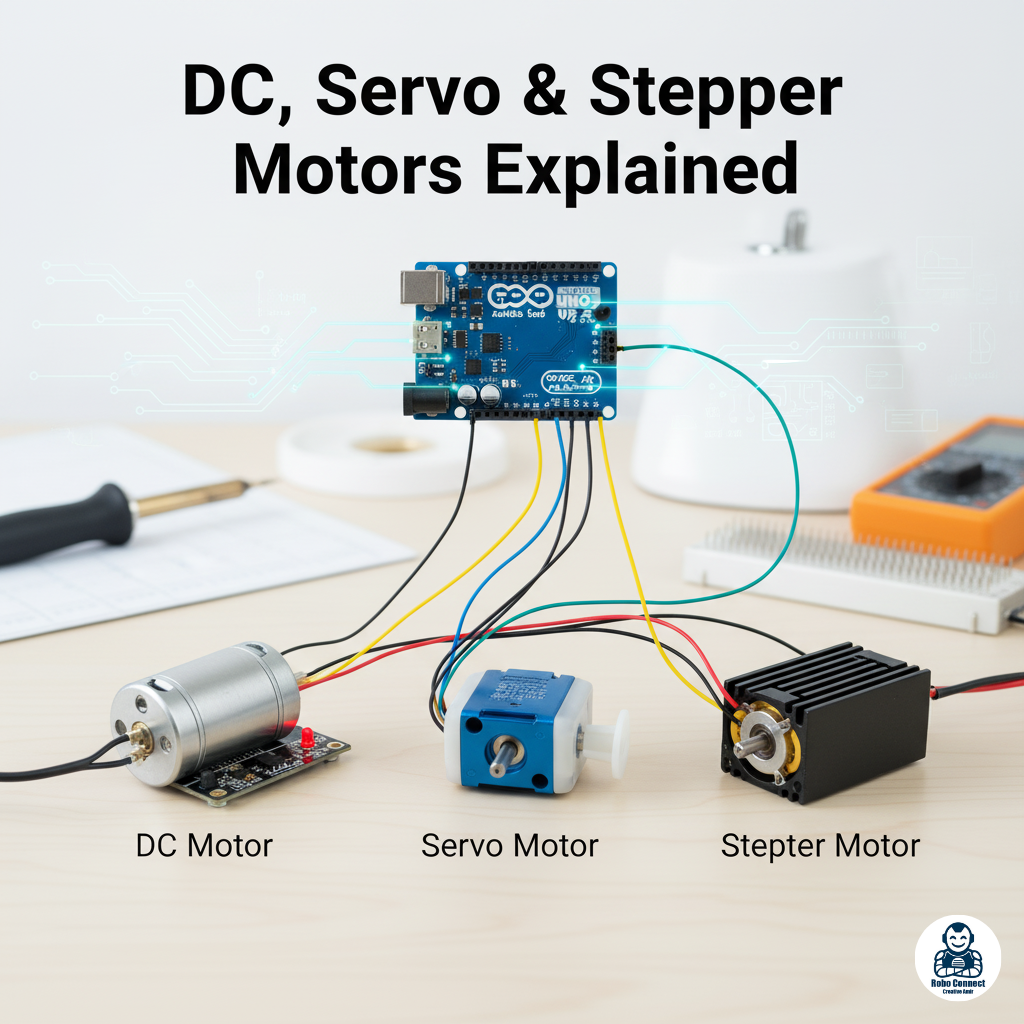

Motors are the muscles of robotics. While microcontrollers (Arduino, Raspberry Pi, ESP) act as the brain, it’s the motors that make robots actually move, lift, and rotate.

Three of the most common motors used in DIY electronics and robotics are:

- DC Motors (fast rotation, continuous spin).

- Servo Motors (precise angle positioning).

- Stepper Motors (precise step‑by‑step movement).

This guide will explain how each motor works, their differences, and which one to use in your project.

- DC Motor

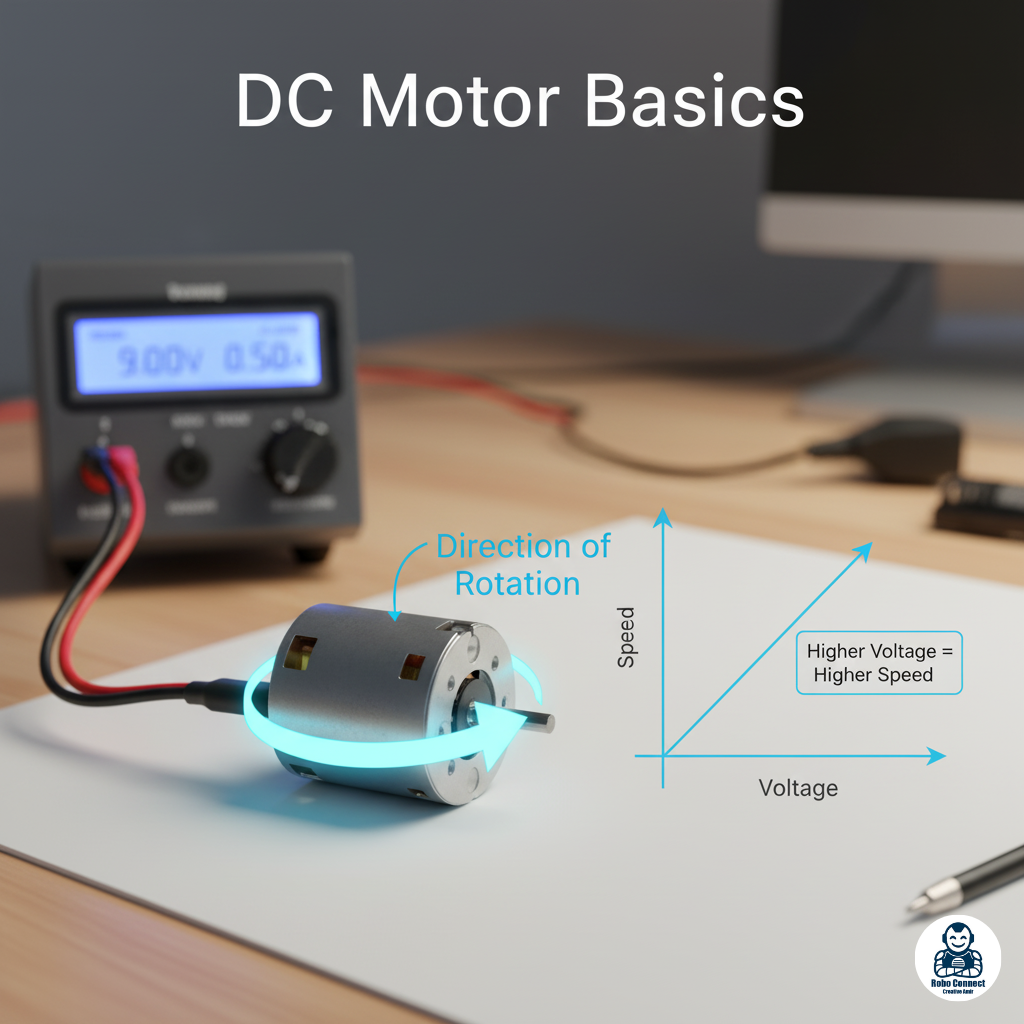

What is it?

A simple Direct Current (DC) motor converts electrical energy into continuous rotary motion. Apply voltage → shaft keeps spinning. Reverse polarity → it spins in the opposite direction.

Features:

- Fast continuous rotation.

- Easy to use.

- Speed can be controlled with PWM (Pulse Width Modulation).

- Requires a motor driver (L298N, L293D, transistor) to handle current.

Best Uses:

- Toy cars or robots.

- Fans, pumps, wheels.

- Applications where speed matters more than precision.

Example (Arduino + DC Motor via L298N):

C++

int motor1Pin1 = 5;

int motor1Pin2 = 6;

void setup() {

pinMode(motor1Pin1, OUTPUT);

pinMode(motor1Pin2, OUTPUT);

}

void loop() {

digitalWrite(motor1Pin1, HIGH);

digitalWrite(motor1Pin2, LOW); // Motor spins forward

delay(2000);

digitalWrite(motor1Pin1, LOW);

digitalWrite(motor1Pin2, HIGH); // Motor spins backward

delay(2000);

}

- Servo Motor

What is it?

A servo motor is a DC motor combined with gears, a feedback circuit, and a control system, allowing it to rotate to a specific position (angle) instead of spinning freely.

Typically: 0° – 180°, sometimes 360° continuous rotation.

Features:

- Can hold and move to a precise angle.

- Controlled with PWM signal.

- Usually has 3 wires: VCC (red), GND (black), Signal (yellow/orange).

Best Uses:

- Robotic arms.

- Steering systems in small cars or boats.

- Camera pan/tilt mounts.

- Any project needing exact positioning.

Example (Arduino + Servo):

C++

#include <Servo.h>

Servo myservo;

void setup() {

myservo.attach(9); // Servo signal wire on pin 9

}

void loop() {

myservo.write(0); // Move to 0°

delay(1000);

myservo.write(90); // Move to 90°

delay(1000);

myservo.write(180); // Move to 180°

delay(1000);

}

- Stepper Motor

What is it?

A stepper motor moves in precise steps (e.g., 1.8° per step = 200 steps per revolution). Instead of spinning freely like a DC motor, it moves in controlled increments.

Features:

- Excellent precision.

- Speed and position controlled by pulses from driver (ULN2003, A4988, etc.).

- Can rotate continuously, but always in discrete steps.

Best Uses:

- 3D printers.

- CNC machines.

- Robotics with precise movement.

- Camera sliders / pan‑tilt rigs.

Example (Arduino + Stepper Motor):

C++

#include <Stepper.h>

const int stepsPerRev = 200;

Stepper myStepper(stepsPerRev, 8, 9, 10, 11);

void setup() {

myStepper.setSpeed(60); // 60 RPM

}

void loop() {

myStepper.step(stepsPerRev); // One full revolution forward

delay(1000);

myStepper.step(-stepsPerRev); // One full revolution backward

delay(1000);

}

Comparison: DC vs Servo vs Stepper

| Feature | DC Motor | Servo Motor | Stepper Motor |

| Type | Continuous rotation | Position control (0°–180°/360°) | Step‑by‑step rotation |

| Control Method | PWM for speed, polarity for direction | PWM for angle | Step pulses from driver |

| Precision | Low (keeps spinning) | High (angle positioning) | Very high (exact steps) |

| Feedback | None | Built‑in feedback | Open‑loop (unless encoder used) |

| Best For | Wheels, fans, quick spin | Robotic arms, camera gimbals | 3D printers, CNC, robotics |

| Cost | Cheapest | Moderate | Moderate‑High |

Which Motor Should You Use?

- Use a DC Motor → If you need simple rotation (wheels, fans).

- Use a Servo Motor → If you need precise angles (robotic arms, steering).

- Use a Stepper Motor → If you need high accuracy in movement (3D printer, CNC, precise robotics).

FAQs

Q1: Can I run a motor directly from Raspberry Pi/Arduino pins?

No! GPIO pins can’t handle high current. Always use a motor driver or transistor circuit.

Q2: Which motor is best for robotics beginners?

Start with DC motors (simple car) → then try servo (arm) → finally stepper (precision projects).

Q3: Do I need external power for motors?

Yes. Motors consume more power than controllers can provide — use batteries or external adapters.

Conclusion

Motors are the driving force (literally!) of robotics.

- DC motors spin wheels and fans.

- Servo motors let robots position arms with precision.

- Stepper motors enable exact movements in 3D printers and CNC machines.

Learn how each works, experiment with beginner projects, and you’ll master the motion side of robotics.