Introduction

Motors are power‑hungry beasts. Your Arduino, ESP, or Raspberry Pi GPIO pins can only provide a tiny amount of current — enough to blink LEDs, but nowhere near enough to spin a motor.

That’s where motor drivers come in. They act as the middleman between your microcontroller (the brain) and motors (the muscles).

In this guide, we’ll explain:

- What a motor driver is.

- The difference between popular motor drivers L293D, L298N, and A4988.

- How to use them in real beginner projects with DC motors, servos, and steppers.

- Example Arduino codes.

What is a Motor Driver?

A motor driver IC (Integrated Circuit) or module is an electronic component that:

- Takes LOW‑power signals from a microcontroller.

- Amplifies them.

- Sends HIGH‑power signals to drive motors safely.

Without a driver, connecting a motor directly to Arduino/RPi pins = burnt board .

Popular Motor Driver ICs / Modules

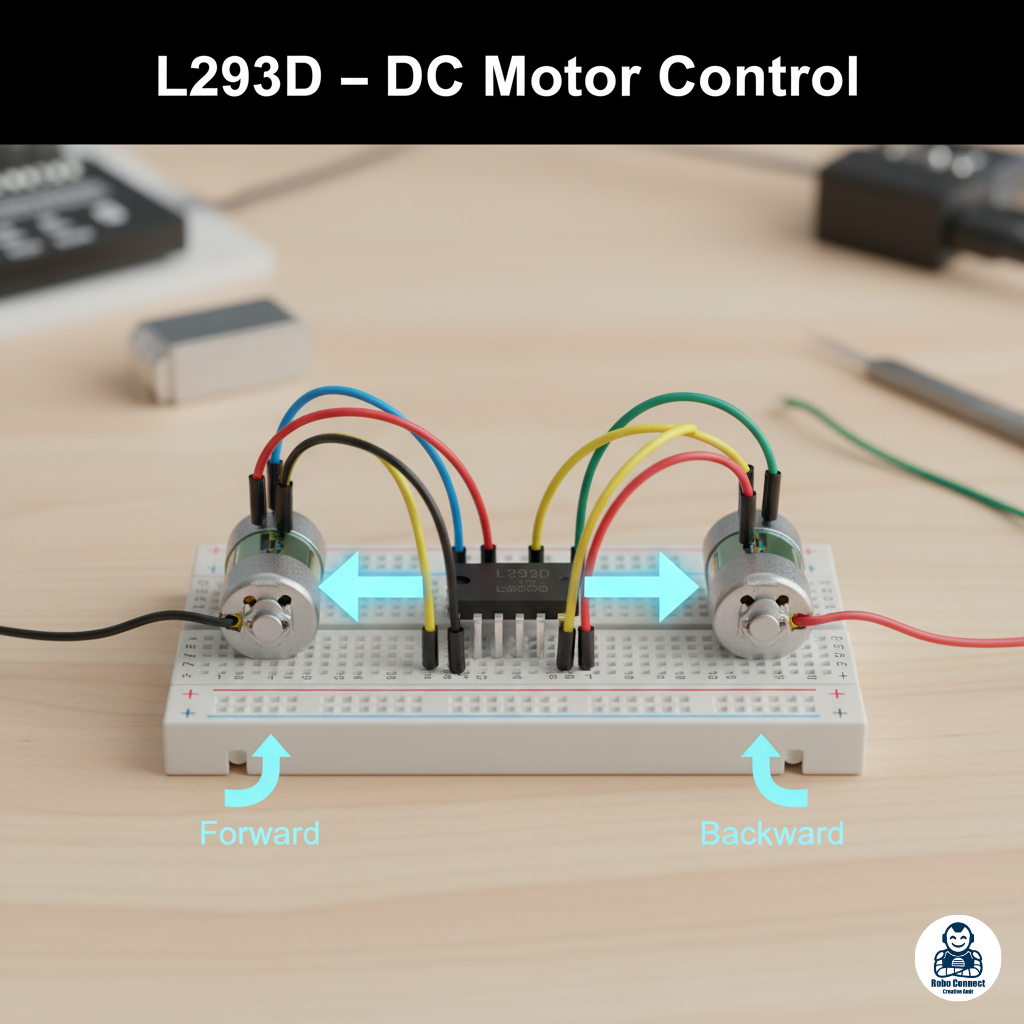

- L293D (Classic DC Motor Driver IC)

- Type: H‑Bridge driver (looks like a small chip).

- Motors Supported: 2 DC motors (or 1 stepper motor).

- Voltage: 4.5V–36V.

- Current per channel: ~600mA.

- Features: Compact, breadboard‑friendly, commonly used in small Arduino robot cars.

Basic Wiring:

- IN1, IN2 → Arduino pins (direction).

- EN1 → Arduino PWM pin (speed).

- OUT1, OUT2 → Motor terminals.

- Vcc1 (logic 5V), Vcc2 (motor supply, e.g., 6V/9V battery).

Code Example (Run DC Motor):

C++

int in1 = 9;

int in2 = 8;

void setup() {

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

}

void loop() {

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW); // Forward

delay(2000);

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH); // Reverse

delay(2000);

digitalWrite(in1, LOW);

digitalWrite(in2, LOW); // Stop

delay(2000);

}

- L298N (Most Popular Motor Driver Module)

- Type: Dual H‑Bridge module (bigger, robust).

- Motors Supported: 2 DC motors (or 1 stepper).

- Voltage: 5V–35V.

- Current per channel: up to 2A (depending on heat sink).

- Features: Often comes as a module with screw terminals & onboard voltage regulator.

Basic Wiring:

- IN1, IN2 → Arduino pins (direction for Motor A).

- ENA → PWM pin (speed).

- OUT1, OUT2 → Motor A.

- Same for IN3, IN4, ENB for Motor B.

- Supply 12V battery to power motors + 5V from Arduino for logic.

Code Example (Control 2 Motors like Car Wheels):

C++

// Motor A pins

int in1 = 9;

int in2 = 8;

int enA = 5;

// Motor B pins

int in3 = 7;

int in4 = 6;

int enB = 10;

void setup() {

pinMode(in1, OUTPUT); pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT); pinMode(in4, OUTPUT);

}

void loop() {

// Forward

digitalWrite(in1, HIGH); digitalWrite(in2, LOW);

digitalWrite(in3, HIGH); digitalWrite(in4, LOW);

analogWrite(enA, 200); // speed

analogWrite(enB, 200);

delay(2000);

// Backward

digitalWrite(in1, LOW); digitalWrite(in2, HIGH);

digitalWrite(in3, LOW); digitalWrite(in4, HIGH);

delay(2000);

// Stop

digitalWrite(in1, LOW); digitalWrite(in2, LOW);

digitalWrite(in3, LOW); digitalWrite(in4, LOW);

delay(2000);

}

This is the #1 driver used in Arduino robot cars.

- A4988 (Stepper Motor Driver)

- Type: Stepper motor driver.

- Motors Supported: Bipolar stepper.

- Voltage: 8V–35V.

- Current per phase: ~2A (with cooling).

- Features: Microstepping (1/2, 1/4, 1/8, 1/16) → smoother motion.

Pins: STEP (pulse pin), DIR (direction pin), ENABLE, VMOT (motor voltage), sleep/reset.

Basic Wiring:

- STEP → Arduino digital pin.

- DIR → Arduino digital pin.

- 4 motor wires → A1, A2, B1, B2 outputs.

- 12V supply to VMOT.

Code Example (Stepper Control):

C++

int dirPin = 2;

int stepPin = 3;

void setup() {

pinMode(dirPin, OUTPUT);

pinMode(stepPin, OUTPUT);

}

void loop() {

digitalWrite(dirPin, HIGH);

for(int x = 0; x < 200; x++) {

digitalWrite(stepPin, HIGH);

delayMicroseconds(1000);

digitalWrite(stepPin, LOW);

delayMicroseconds(1000);

}

delay(1000);

digitalWrite(dirPin, LOW); // Reverse

for(int x = 0; x < 200; x++) {

digitalWrite(stepPin, HIGH);

delayMicroseconds(1000);

digitalWrite(stepPin, LOW);

delayMicroseconds(1000);

}

delay(1000);

}

Widely used in 3D printers, CNC machines, and camera sliders.

Comparison Table

| Feature | L293D | L298N | A4988 |

| Type | H‑Bridge IC | H‑Bridge Module | Stepper Driver |

| Motors Supported | 2 DC / 1 stepper | 2 DC / 1 stepper | 1 Bipolar stepper only |

| Current Capacity | ~600mA per motor | ~2A per channel | ~2A per phase |

| Voltage | 4.5–36V | 5–35V | 8–35V |

| Best Use Cases | Small robots, toys | Robot cars, heavy DC motors | CNC, 3D printing, precise robotics |

Which One Should You Use?

- L293D → Compact, beginner‑friendly, small robot cars, low‑power motors.

- L298N → Versatile, can handle bigger robot cars/ROVs, widely supported.

- A4988 → Advanced robotics requiring precise movement (3D printer, CNC).

FAQs

Q1: Why can’t I connect motor directly to Arduino pins?

Arduino pins only provide ~40mA max; DC motors need hundreds of mA to Amps → fry danger!

Q2: Can one driver run both DC and Stepper?

Yes, L293D and L298N can do either 2 DCs or 1 stepper, while A4988 is ONLY for steppers.

Q3: Which is easier for complete beginners?

The L298N module → easy wiring with screw terminals.

Conclusion

Motor drivers are the unsung heroes of robotics projects.

- L293D: Tiny, educational, great for school robotics.

- L298N: Robust, perfect for most DIY cars and bots.

- A4988: Precision driver powering 3D printers and CNC machines.

Pick your driver based on motor type + current needs. Once you master them, you can make wheels spin, robot arms bend, and CNC machines carve.